Leading Poultry Processor Evaluates New Plastic Pallet Designed for Food Operations

Rocco Enterprises, a poultry processing company headquartered in Virginia's Shenandoah Valley, is among the country's largest suppliers of turkey and institutional chicken. Since its founding more than 60 years ago, the company has cultivated a worldwide reputation for quality products and innovative practices.

In keeping with its tradition of innovation, Rocco was among a small roster of companies that agreed to field test <%=company%>'s newest entry into the plastic pallet market, the RackoCell pallet. This heavy-duty, rackable, 40-inch by 48-inch USDA-type plastic pallet is specifically designed for applications such as food processing where durability and sanitation are critical.

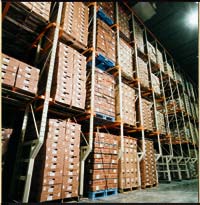

Rocco put the RackoCell pallets into service in its most demanding environment: the Rocco Distribution Center, which stores up to 22 million pounds of fresh and frozen turkey and chicken prior to shipment to customers in the U.S. and overseas. Rocco sells its fresh turkeys under the Shady Brook Farms label, and has focused on the food service industry for its chicken products, supplying many of the major chain restaurants in the eastern part of the country. Much of the company's dark meat chicken is destined for Asia, Eastern Europe, the Middle East and Latin America.

Due to its punishing environment, the distribution center presented perhaps the most challenging test of the RackoCell's performance. The pallet was used in a closed-loop system between Rocco's chicken processing plant and the warehouse, and was subjected to extreme temperatures and multiple handlings.

In the processing plant, boxes of fresh product are loaded onto the pallets -- 40 to 60 boxes per pallet -- and moved by forklift into a cooler where they are stored in racks. The loaded pallets are then taken to the loading dock to be trucked a short distance to the distribution center for freezing and further storage.

From the center's receiving dock, the fully loaded pallets are transported via forklift into a blast freezer, with a temperature of -30° F and windchill of -100°, where they are kept for 24 to 48 hours. The frozen pallet-loads are next moved to a machine to remove the spacers put between the layers of product to speed the freezing process. Finally, the pallets are racked in a giant frozen storage area awaiting shipment to customers.

"In our operation, a pallet gets handled between eight and 12 times from the time product is produced until it's on the truck headed for the customer," says Rocco's distribution manager, Larry Brown. "We're interested in getting the maximum number of usages from a high-value pallet like the RackoCell."

While Rocco previously used some plastic pallets in its distribution operations in the mid-'90s, there were some durability and sanitation issues with them. Today, the center operates almost entirely using wooden pallets, which have their own problems. Says Brown, "We use hundreds of thousands of wooden pallets a year. In my experience, for every eight to ten handlings of a wooden pallet, you're going to incur enough damage that it's going to need repair. In this test application, we're most interested in looking at the handling characteristics and the durability of the product."

Racking durability is a key criterion for Rocco, as it is for most food processors and especially in freezer and refrigerated applications where energy is a prime cost, Brown says. Typical loads in Rocco's racking applications range from 1,200 to 1,800 pounds. The RackoCell pallet, made from polypropylene for added stiffness and incorporating structural elements that enhance racking performance, is designed to edge-rack loads of up to 2,200 pounds. After a month in testing at Rocco, the pallets have shown no cracking or deflection problems.